Bagging/Canning-Heat sealing/capping-packing-dividing Picking-palletizing-packing-AGV-incoming and outgoing

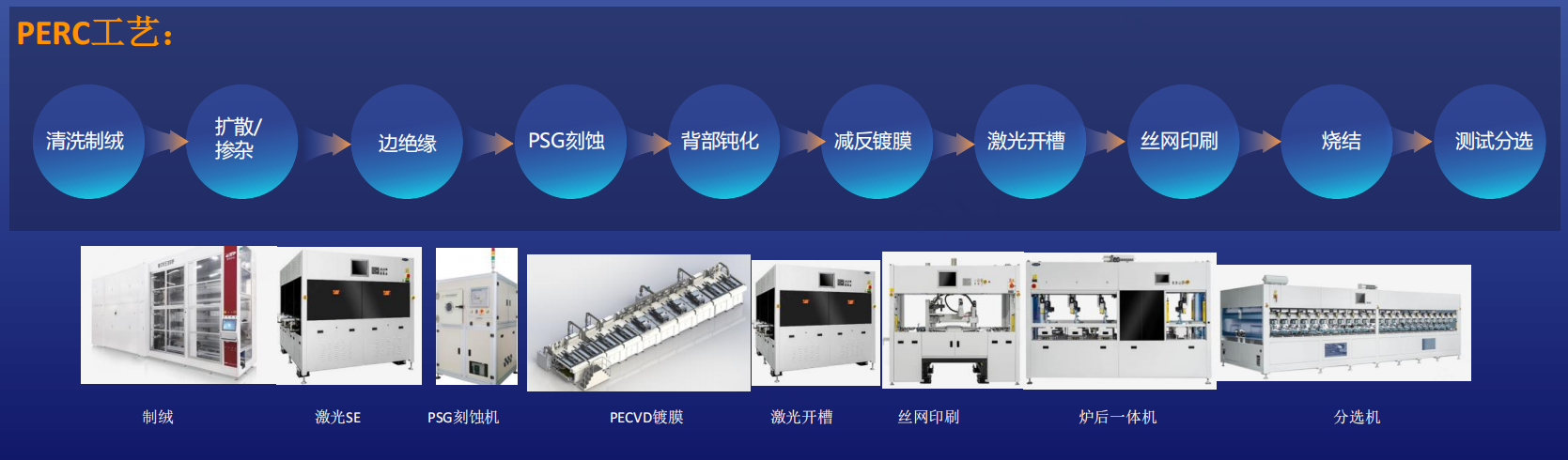

In the photovoltaic industry, there are long distances between workshops for loading, unloading and transporting cells. Manual transportation is time-consuming and labor-intensive, and it is easy for the transportation to be delayed, resulting in the accumulation of goods at the end of the line. Intelligent robots replace the original manual work and help the photovoltaic industry to upgrade intelligently and digitally, replacing more than 80% of porters and improving logistics efficiency.

Through simple drag-and-drop programming or graphical programming, customers can let the robot move according to the user's ideas and process requirements, replacing manual work. It is easy to use, can move easily in the work area, and greatly improves flexibility and user experience.

While traditional automation can only be implemented in an all-or-nothing manner, robots can allow automakers to automate specific tasks. Robots can work side by side with employees, increasing employee output, ensuring consistency, and allowing them to work in a single work area. handle more parts of the production process and realize payback quickly.

In order to meet the increasingly stringent requirements for electronic product assembly and processing, robots are also specially designed according to the needs of 3C manufacturing. Their miniaturization and simplicity enable high-precision and rapid production of electronic assembly. While improving product production efficiency, it also reduces the equipment footprint and reduces the company's land costs.

Breakthroughs in new material technology will make material products intelligent to a large extent, with sensing functions, feedback functions, information recognition and accumulation functions, response functions, self-diagnosis capabilities, self-recovery capabilities, and self-adjustment capabilities. These smart materials can meet the requirements for the development of artificial intelligence.

Prospects of the artificial panel industry

1. The "14th Five-Year Plan" requires improving the production efficiency of artificial panels, automating and integrating plywood production lines, etc.

2. In the past two years, a large number of production lines with substandard efficiency and environmental protection have been shut down, resulting in considerable demand for new production lines.